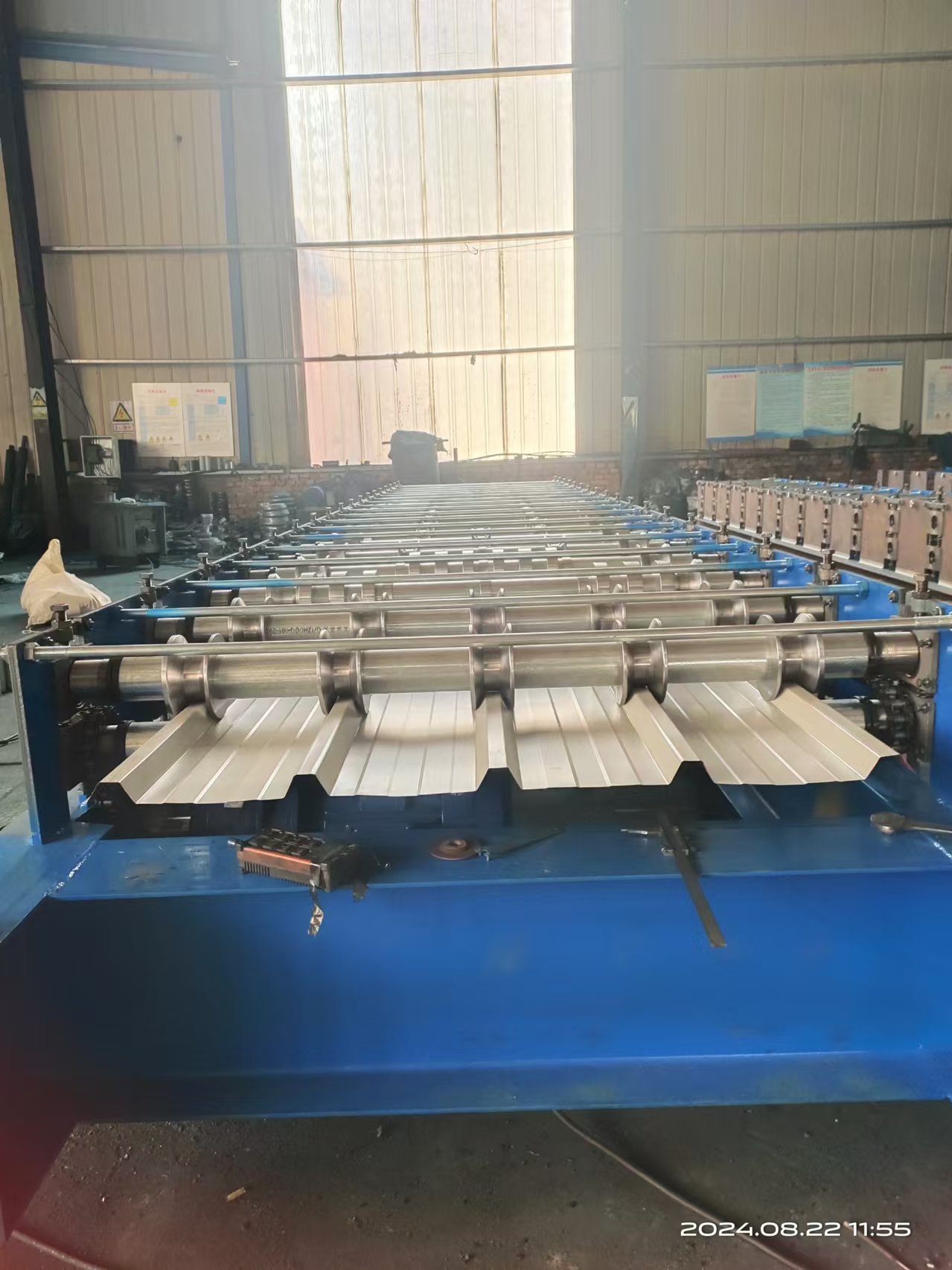

1000-type trapezoidal color steel tile press machine

1000-type trapezoidal color steel tile press machine: A highly efficient and precise tool for color steel processing

In the field of color steel processing, the 1000-type trapezoidal color steel tile press machine is highly favored for its outstanding performance and wide applicability. Now, let’s introduce this powerful equipment in detail.

I. Working Principle

The 1000-type trapezoidal color steel tile press machine mainly processes color steel plates into trapezoidal shapes through a series of roll-forming processes. First, the color steel plate is fed into the machine’s inlet. Then, it is gradually bent and pressed by multiple rollers of different shapes and sizes. The design and arrangement of these rollers are carefully calculated to ensure that the color steel plate can be accurately formed into the predetermined trapezoidal shape. Throughout the process, the motor provides power and drives the rollers to rotate through the transmission system, realizing continuous processing of the color steel plate.

II. Structural Composition

- Frame: As the basic supporting structure of the equipment, the frame of the 1000-type trapezoidal color steel tile press machine is usually welded from high-strength steel and has sufficient stability and strength to withstand various forces generated during the operation of the equipment.

- Roller system: This is the core part of the tile press machine and consists of multiple rollers of different shapes. Each roller is precisely processed with a smooth surface to ensure that there are no scratches or deformations on the color steel plate during the forming process. The material of the rollers is generally high-quality alloy steel with high hardness and wear resistance to ensure long-term use.

- Transmission system: Responsible for transmitting the power of the motor to the roller system so that the rollers can rotate at an appropriate speed. The transmission system usually includes components such as a motor, reducer, coupling, and transmission shaft. The matching precision of these components directly affects the operation stability and forming precision of the equipment.

- Control system: Adopting advanced automatic control technology, it can achieve precise control of the equipment. Operators can set various parameters such as the rotation speed of the rollers, feeding speed, and forming size through the control panel. The control system also has fault diagnosis and alarm functions to detect and solve problems in the operation of the equipment in a timely manner.

III. Performance Characteristics

- High production efficiency: The 1000-type trapezoidal color steel tile press machine has a relatively high production efficiency and can process a certain length of trapezoidal color steel plate per minute. This greatly improves production efficiency and meets the needs of large-scale production.

- High forming precision: Due to the use of a precise roller system and advanced control technology, this equipment can ensure the forming precision of trapezoidal color steel plates with small dimensional errors and regular shapes. This provides convenience for subsequent installation and use.

- Easy operation: The control system of the equipment is simple to operate and easy to master. Operators can quickly become proficient in operating the equipment after simple training. At the same time, the equipment also has a high degree of automation, which can reduce the labor intensity of manual operation.

- Strong adaptability: The 1000-type trapezoidal color steel tile press machine can process color steel plates of different thicknesses and materials, with strong adaptability. Whether it is ordinary color steel plate or special material color steel plate, it can be efficiently processed on this equipment.

- Convenient maintenance: The structural design of the equipment is reasonable, and each component is easy to disassemble and install. In daily maintenance, operators can easily clean, lubricate, and inspect the equipment to ensure its normal operation.

IV. Application Fields

The 1000-type trapezoidal color steel tile press machine is widely used in fields such as construction, industrial plants, warehouses, and cold storages. The trapezoidal color steel plates produced by it have the advantages of beauty, durability, waterproofing, and heat insulation and are widely used for roofing and wall covering. In addition, this equipment can also be customized according to the special needs of customers to produce color steel plates of different shapes and sizes to meet the needs of various special projects.

In conclusion, the 1000-type trapezoidal color steel tile press machine is a color steel processing equipment with outstanding performance and powerful functions. With its high production efficiency, high-precision forming, simple operation, and good adaptability, it brings great convenience to the color steel processing industry. Whether it is for large-scale production or small-batch customization, this equipment can meet the needs of users and is an ideal choice in the field of color steel processing.