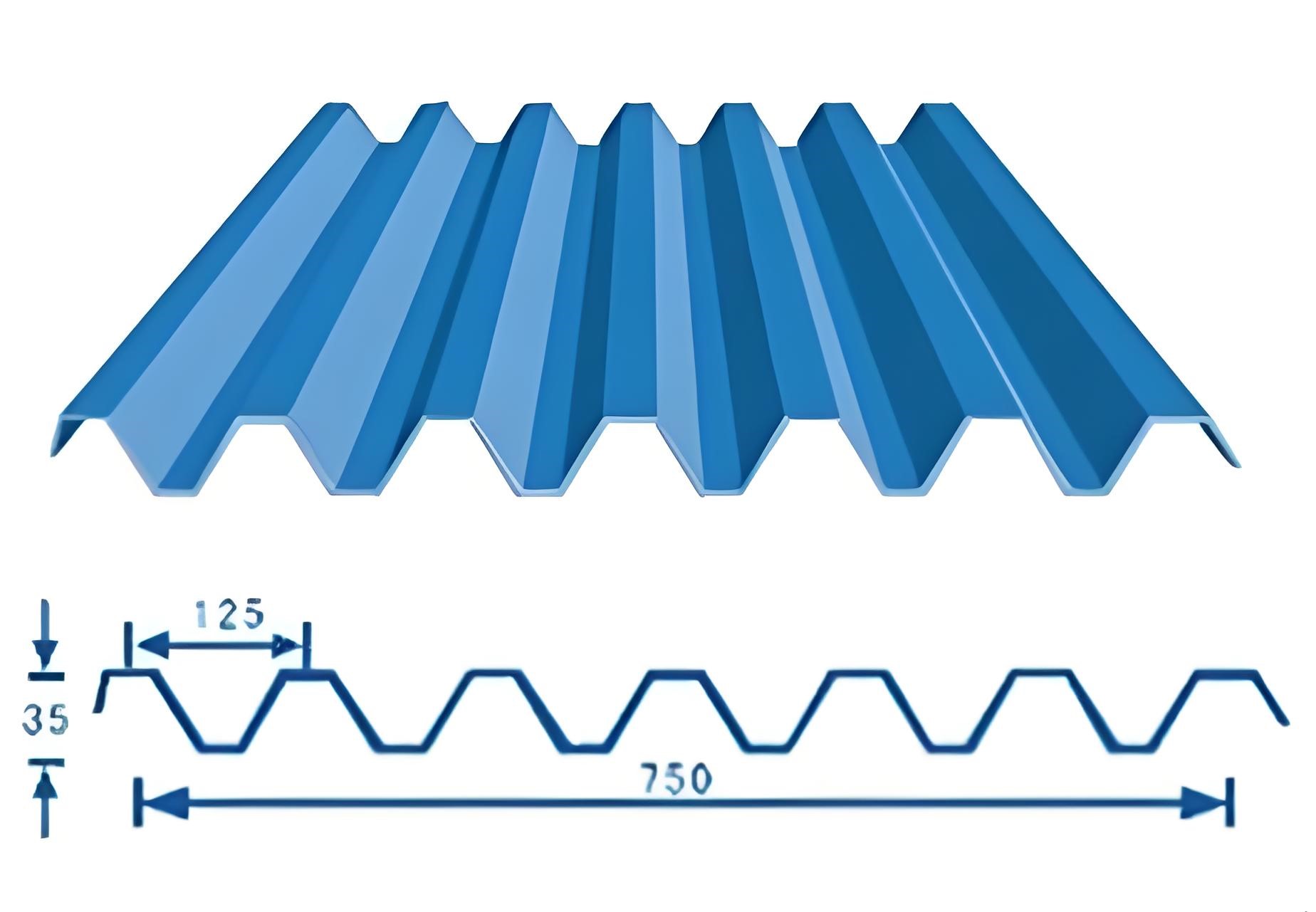

750 horizontal hanging plate color steel tile press machine

The 750 horizontal hanging plate color steel tile press machine is a device used for processing color steel horizontal hanging plates and is widely used in the construction industry. The following is an introduction to it and common configuration standards:

Equipment Introduction:

Appearance and forming effect: The profiled plates produced by this tile press have a flat appearance and uniform corrugations, which are both solemn and elegant as well as beautiful and novel.

Performance advantages: It has characteristics such as high strength, a high degree of production automation, low cost, and durability. The products it produces are used for horizontal hanging wall tiles in various industrial plants and warehouses. They can also be used as roofing tiles. They have the advantages of high wave crests and great strength. The overlapping installation is safe and reliable, and it has strong waterproof and typhoon resistance performance. Moreover, the 750 horizontal hanging plate color steel tile press machine solves the roof leakage problem of conventional series of profiled plates.

Configuration Standards:

Forming part:

Forming shaft: Generally made of 45# steel with a diameter of about 70mm. After heat treatment processes such as quenching and tempering, its strength and precision are ensured. If the thickness of the color steel tile to be pressed is greater, the forming shaft will be larger, such as with a diameter of 80mm.

Forming wheel: The material is mostly 45# forged steel that is quenched and hard chrome plated. This treatment method can improve the hardness and wear resistance of the forming wheel and ensure that it can stably press color steel plates during long-term use.

Number of forming rows: Common numbers of forming rows include 12 rows, 13 rows, 14 rows, 15 rows, 18 rows, etc. The more rows there are, the better the forming effect and precision control of the plate.

Transmission part:

Transmission method: Chain wheel and chain transmission is adopted. The specification of the chain is 1 inch.

Motor: The motor is the power source of the equipment. The power is generally between 5.5kW and 7.5kW. The specific power size depends on production needs.

Frame part:

Large frame: The large frame is the support structure of the equipment and needs to have sufficient strength and stability. Common large frame materials include 300H steel, 350H steel, etc.

Middle plate: The middle plate plays a role in connecting and supporting various parts of the equipment. Its thickness is generally 14mm.

Control system:

Electronic control system: Industrial computer PLC frequency conversion control is adopted, which can realize automated production, improve production efficiency and precision, and can monitor and control the running state of the equipment in real time.

750 horizontal hanging plate color steel tile press machine Shearing system: Equipped with a hydraulic die shearing device. The shearing power is 4kW. The material of the shearing knife is mostly Gr12, which is formed by high-temperature quenching and has high hardness and service life.

Other configurations:

Feeding device: Includes a feeding introduction platform, etc., to facilitate the feeding of color steel plates and ensure smooth and stable feeding.

Random accessories: Usually equipped with accessories such as a color steel coil loading frame.